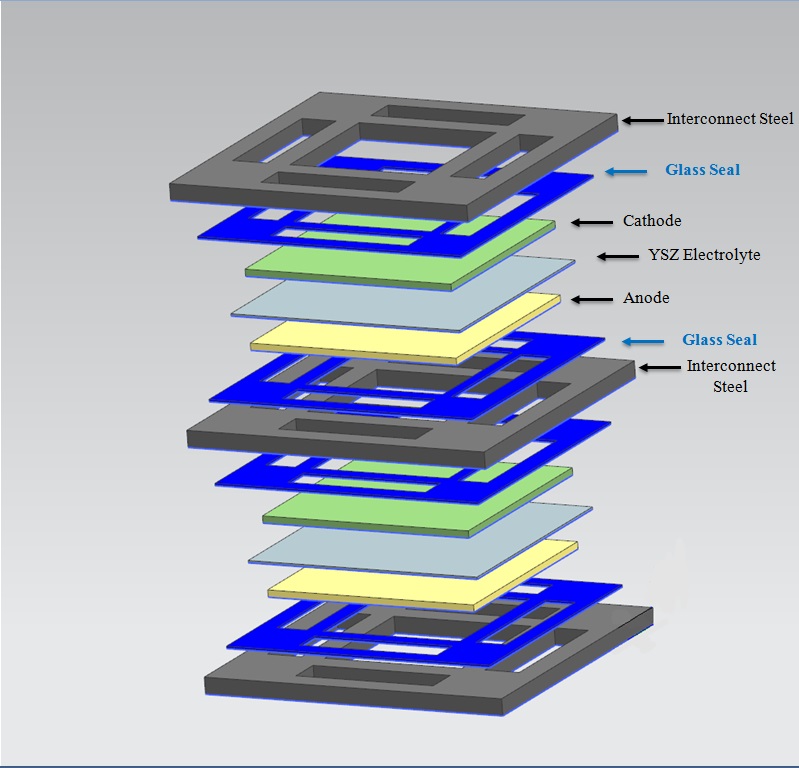

Mo-Sci has taken two distinct approaches to developing high-temperature sealant materials for solid oxide fuel cells (SOFCs) and other applications such as sodium-ion batteries. The first is the traditional glass-ceramic seal in which the glass crystallizes and bonds to seal components.

The second approach bonds to metals and ceramics, but the alkali-free composition of the glass has been tailored to operate in a viscous state while resisting crystallization. Compliant or viscous glass seals are a new class of SOFC seal and are designed to be vitreous at the SOFC stack operating temperatures. Viscous seals have the potential to reduce the risk that thermal stresses will result in catastrophic seal failure through viscous healing of cracks if they form during thermal cycling.

Note: This is an area of current research and development and additional compositions are in the commercialization process at this time. Please contact MO-SCI about the availability of other compositions if the options above will not suit your application.

Mo-Sci Sealing Glass Selector

| wdt_ID | Glass | Glass Seal Type | Applicable Materials | Max Operational Temp (°C) | Min Firing Temp (°C) | Max Firing Temp (°C) | CTE Crystalized (ppm/°C) | CTE As Cast (ppm/°C) | Tc (°C) | Td (°C) | Tg (°C) | Density (g/cm3) | Resistant to Alkali | Color |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | GL1701 | glass-ceramic | Alumina, Aluminum Nitride, Mullite, Sapphire, Steatite, Yttria | 1,600 | 1,200 | 6.00 | 1,000 | 1,200 | 750 | 2.60 | No | white | ||

| 2 | GL1702 | glass-ceramic | Alumina, Yttria, Sapphire, Steatite | 1,200 | 900 | 1,200 | 8.00 | 7.90 | 880 | 697 | 670 | 3.50 | No | white |

| 3 | GL1862 | glass-ceramic | Alloy 52, Ferrite, Forsterite, Stainless Steel 4XX, Titanium, YSZ, Zirconia | 1,000 | 850 | 925 | 10.30 | 10.00 | 1,028 | 762 | 725 | 3.40 | No | white |

| 4 | GL1873 | glass-ceramic | Alumina, Yttria, Sapphire, Steatite | 1,000 | 800 | 820 | 7.60 | 8.30 | 827 | 700 | 651 | 2.60 | No | white |

| 5 | GL1850 | glass-ceramic | Aluminum Nitride, Mullite, Silicon Carbide, Silicon Nitride, Tungsten | 970 | 1,250 | 1,250 | 3.50 | 3.90 | 1,250 | 849 | 815 | 2.40 | No | white |

| 6 | GL1870 | glass-ceramic | Alumina, Yttria, Sapphire, Steatite | 910 | 1,020 | 1,020 | 9.10 | 9.60 | 1,037 | 754 | 724 | 3.20 | No | white |

| 7 | GL1883 | glass | Aluminum Nitride, Mullite, Silicon Carbide, Silicon Nitride, Tungsten | 900 | 950 | 970 | 3.50 | 599 | 462 | 2.10 | No | white | ||

| 8 | GL1810 | glass-ceramic | Inconel Alloys, Stainless Steel 3XX, Copper | 900 | 820 | 1,000 | 16.00 | 10.00 | 815 | 682 | 575 | 2.40 | No | white |

| 9 | GL1729 | glass-ceramic | Alloy 52, Ferrite, Forsterite, Stainless Steel 4XX, Titanium, YSZ, Zirconia | 900 | 790 | 890 | 11.00 | 10.90 | 890 | 750 | 690 | 3.50 | No | white |

| 10 | GL1497 | glass-ceramic | Alloy 52, Ferrite, Forsterite, Stainless Steel 4XX, Titanium, YSZ, Zirconia | 900 | 760 | 830 | 10.00 | 9.60 | 830 | 718 | 640 | 3.30 | No | brown |